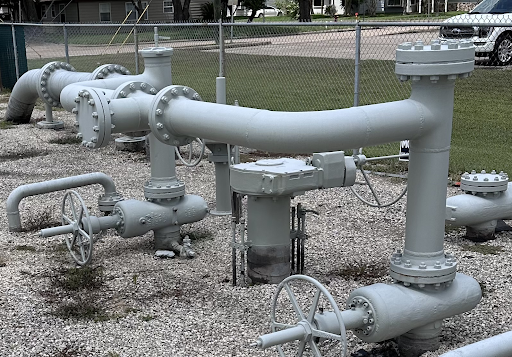

Piping flanges are important components used to connect pipes, valves, pumps, and other equipment in various industrial applications. Ensuring their proper installation is vital for maintaining the integrity of the entire piping system. This article will explore the correct techniques and tips for installing piping flanges to prevent common issues and enhance system performance.

“Learn more about piping flanges in our guide.”

Importance of Proper Flange Installation

Correct installation of piping flanges ensures:

- Leak prevention: Properly installed flanges provide a secure seal, preventing leaks.

- System integrity: Correct alignment and torque prevent mechanical failures.

- Safety: Reduces the risk of accidents and environmental hazards.

- Longevity: Extends the life of the piping system and reduces maintenance costs.

Preparation for Flange Installation

Preparation is key to successful flange installation. Follow these steps to ensure you are ready for the installation process.

Gather Tools and Materials

Ensure you have all necessary tools and materials on hand before beginning the installation. This includes:

- Flanges

- Gaskets

- Bolts and nuts

- Torque wrench

- Alignment tools

- Lubricants

Inspect Components

Inspect all components for defects or damage before installation. Check flanges for cracks, deformation, or corrosion. Ensure gaskets are free from damage and bolts and nuts are in good condition.

Clean Surfaces

Clean the flange faces and gasket surfaces to remove any debris, dirt, or oil. This ensures a better seal and reduces the risk of leaks.

Step-by-Step Flange Installation Process

Follow these detailed steps to install piping flanges correctly.

Step 1: Align the Flanges

Proper alignment of the flanges is crucial to avoid stress and ensure a tight seal. Use alignment tools if necessary to achieve perfect alignment.

1. Position the Flanges: Bring the flanges into position and ensure they are parallel.

2. Check Alignment: Use an alignment tool or a straight edge to check that the flange faces are aligned correctly.

Step 2: Insert the Gasket

The gasket is essential for creating a tight seal between the flanges.

1. Choose the Right Gasket: Select a gasket material that is compatible with the operating conditions and media.

2. Position the Gasket: Place the gasket between the flange faces, ensuring it is centered and not damaged.

Step 3: Insert and Tighten Bolts

Bolting the flanges together requires even pressure to ensure a proper seal.

1. Lubricate Bolts and Nuts: Apply a suitable lubricant to the threads and under the heads of the bolts to ensure smooth tightening.

2. Insert Bolts: Insert bolts into the bolt holes, starting with the bolts on opposite sides of the flange.

3. Hand Tighten: Hand tighten the bolts to hold the flanges together.

4. Torque in Sequence: Using a torque wrench, tighten the bolts in a crisscross pattern to ensure even pressure distribution. Follow the recommended torque values provided by the manufacturer.

Step 4: Final Tightening

Ensure the flanges are securely fastened to prevent leaks.

1. Re-Torque Bolts: After the initial tightening, re-torque the bolts to the specified value to account for any gasket compression.

2. Check for Leaks: Inspect the flange connection for any signs of leaks or misalignment.

Best Practices for Flange Installation

Following these best practices can help ensure a successful flange installation.

Use the Right Tools

Always use the appropriate tools for the job, including alignment tools, torque wrenches, and lubricants. This ensures accuracy and prevents damage to the components.

Follow Manufacturer Guidelines

Adhere to the manufacturer’s specifications and guidelines for torque values, gasket selection, and installation procedures. This ensures the flanges are installed correctly and safely.

Conduct Regular Inspections

Regularly inspect flange connections for signs of wear, damage, or leaks. Early detection of issues can prevent major failures and reduce maintenance costs.

Train Personnel

Ensure that all personnel involved in flange installation are properly trained and understand the importance of following correct procedures. This reduces the risk of errors and enhances the overall safety of the operation.

Common Mistakes to Avoid

Avoiding common mistakes can significantly improve the reliability of flange installations.

Over-Tightening or Under-Tightening Bolts

Over-tightening can damage the flange and gasket, while under-tightening can lead to leaks. Always use a torque wrench and follow the specified torque values.

Using the Wrong Gasket Material

Using an incompatible gasket material can result in chemical reactions, degradation, and leaks. Always select gaskets based on the operating conditions and media.

Ignoring Flange Alignment

Misaligned flanges can cause stress, leaks, and mechanical failures. Always check and correct alignment before tightening the bolts.

Failing to Inspect Components

Installing damaged or defective components can compromise the entire system. Always inspect flanges, gaskets, and bolts before installation.

Conclusion

Proper installation of piping flanges is essential for ensuring the safety, reliability, and efficiency of piping systems. By following the correct techniques and best practices, you can prevent common issues and extend the lifespan of your system. Regular inspections, using the right tools, and following manufacturer guidelines are key to successful flange installation.

for more info: https://www.texasflange.com/lp12/

FAQs

What are the steps for proper flange installation?

The steps include aligning the flanges, inserting the gasket, inserting and tightening bolts, and performing final tightening.

Why is flange alignment important?

Proper alignment prevents stress, leaks, and mechanical failures in the piping system.

How do I choose the right gasket for flange installation?

Select a gasket material compatible with the operating conditions and the media being transported.

What is the correct sequence for tightening flange bolts?

Tighten the bolts in a crisscross pattern to ensure even pressure distribution and a proper seal.

What tools are essential for flange installation?

Essential tools include alignment tools, torque wrenches, and lubricants.

Why is regular inspection of flanges important?

Regular inspections help detect and address issues early, preventing major failures and reducing maintenance costs.

What common mistakes should be avoided during flange installation?

Avoid over-tightening or under-tightening bolts, using the wrong gasket material, ignoring flange alignment, and failing to inspect components.

How can proper training of personnel improve flange installation?

Proper training ensures personnel understand and follow correct procedures, reducing the risk of errors and enhancing overall safety.