Getting your pipe flanges dimensions right matters more than you might think. A small measurement error can cause leaks, safety hazards, and expensive rework. Whether you’re replacing an old flange or planning a new installation, accurate measurements are the foundation of a secure piping system. This is essential knowledge if you want to learn How to Measure Pipe Flange Dimensions Correctly.

This guide walks you through measuring all common types of pipe flanges correctly. We’ll cover everything from standard steel pipe flanges to specialty items, giving you the confidence to measure like a pro and ensuring you understand How to Measure Pipe Flange Dimensions Correctly.

Gather the Right Tools for Accurate Measurements

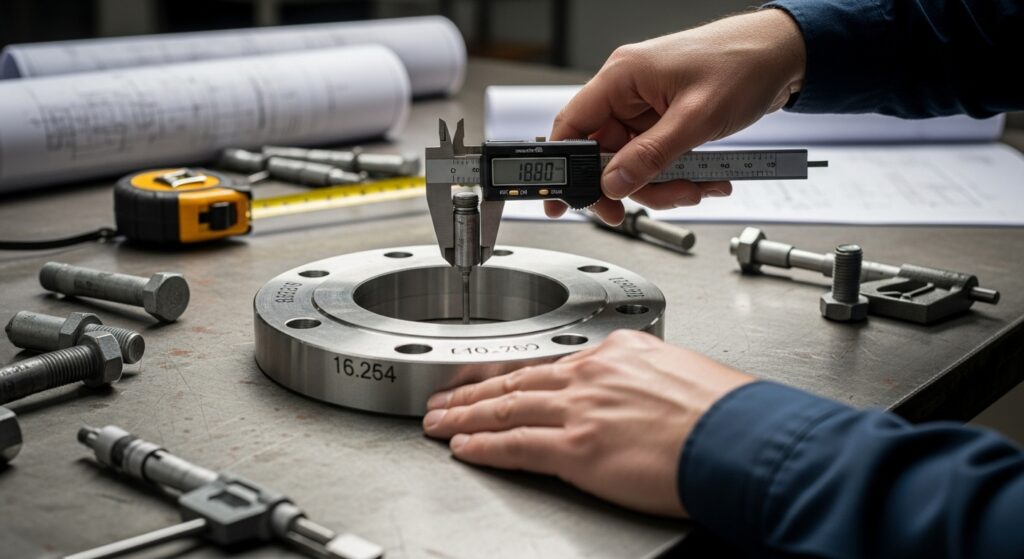

You don’t need expensive gear, but using the right tools prevents mistakes. Here’s what we recommend:

- Digital Calipers: Essential for measuring bolt holes, thickness, and bore diameter accurately.

- Tape Measure or Ruler: Suitable for larger measurements like the outside diameter.

- Bolt Gauge: Helpful for quickly determining bolt size, but calipers work too.

A quick tip: while a tape measure can give you a rough idea, calipers are non-negotiable for precise pipe flanges dimensions. The small investment can save you from major headaches later.

The 6 Essential Dimensions You Need to Identify

To correctly identify any flange, you need these six measurements. They work for all standard types of pipe flanges.

1. Nominal Pipe Size (NPS)

This tells you what pipe size the flange connects to – whether it’s a common 2 pipe flange or larger sizes.

- How to measure: Measure the inner diameter (ID) of the flange bore. Compare this to a standard chart to find your NPS.

- One thing to consider: Don’t assume the flange OD indicates pipe size. The bore measurement is what actually matters.

2. Outside Diameter (OD)

The total width across the flange face.

- How to measure: Measure straight across from one outer edge to the opposite edge.

3. Bolt Circle Diameter (BCD)

This critical dimension ensures your bolt holes will align properly.

- How to measure: For even-numbered bolt patterns, measure from the center of one bolt hole to the center of the opposite hole. For odd numbers, measure from the back of one hole to the far edge, then subtract the bolt hole radius.

4. Bolt Hole Diameter and Count

- How to measure: Use calipers to measure one bolt hole’s diameter, then count all holes.

5. Flange Thickness

- How to measure: Measure from the gasket face to the back of the flange.

6. Pressure Class Identification

The pressure rating (150#, 300#, etc.) isn’t directly measured but determined through your other measurements. Higher classes have more bolts, larger BCDs, and greater thickness. You’ll need to cross-reference your measurements with ASME B16.5 standards, which you can find through reputable suppliers like Texas Flange.

Special Considerations for Different Flange Types

While the basic measurements stay the same, some types of pipe flanges need extra attention:

Measuring Decorative Pipe Flanges

Decorative pipe flange products follow different rules. They’re made for appearance, not pressure containment. You still measure the same way, but don’t expect them to match standard pipe flanges dimensions charts.

Small Bore Flanges Like 2″ Size

A 2 pipe flange requires extra precision with your calipers. Small measurement errors here have bigger consequences than with larger flanges. Take your time and double-check each dimension.

Steel Pipe Flanges

When measuring steel pipe flanges, watch for corrosion that might affect your measurements. Clean the surfaces first, and measure multiple spots to ensure you’re getting the true dimension.

Step-by-Step Measurement Process

Here’s our field-tested approach to measuring any flange:

- Start with the bore to determine NPS

- Measure the OD for your first class indicator

- Find the BCD – this is your most critical alignment dimension

- Count and measure bolt holes

- Measure thickness to complete your data set

- Compare all measurements against ASME B16.5 standards

We’ve helped thousands of customers through this process. Our team can review your measurements if you’re uncertain – just give us a call with your numbers.

Frequently Asked Questions

What’s the most common measuring mistake?

People often measure the flange OD and call that the pipe size. The pipe size comes from the bore measurement, not the flange outside diameter.

Can I measure a flange that’s still installed?

You can get close. Measure from bolt outside to opposite bolt outside, then subtract one bolt diameter for BCD. For bore, you might need system drawings or to measure the connected pipe OD.

How do decorative pipe flanges differ?

Decorative pipe flange products aren’t made to pressure standards. They might look like standard steel pipe flanges but have different dimensions and shouldn’t be used in pressurized systems.

My measurements don’t match standard charts – why?

You might have a specialty, metric, or older standard flange. Some industries use proprietary designs. We specialize in helping identify these unusual flanges at PipingFlange.com.

Where can I find reliable dimension charts?

Reputable suppliers like Texas Flange provide accurate ASME B16.5 charts online. Always cross-reference with current standards rather than old printed charts.

Do I need different tools for large flanges?

The same tools work, but for flanges over 24 inches, a tape measure is fine for OD and BCD. Still use calipers for bolt holes and thickness.

Get Confident With Your Flange Measurements

Measuring pipe flanges dimensions correctly takes practice, but it’s a skill worth mastering. Remember that small errors in measurement can lead to big problems in operation. When you’re working with critical steel pipe flanges, precision matters.

If you’re ever unsure about your measurements, we’re here to help. Our team has the technical expertise to verify your dimensions and ensure you get exactly what you need. We provide certified flanges with guaranteed dimensions that match industry standards.

Ready to order or need verification? Contact us today with your measurements, and we’ll make sure you get the right flange for your application.