Pipe flanges are the unsung heroes of industrial systems, forming the backbone of connections between pipes and various components. These unassuming yet critical components play a pivotal role in maintaining the integrity of your piping system. In this section, we’ll define pipe flanges and highlight the vital role they play. We’ll also shed light on the significance of bolted connections and gaskets in ensuring a secure and leak-free infrastructure.

“Learn more about piping flanges in our guide.”

Types of Pipe Flanges

1. Weld Neck Flange

The weld neck flange, characterized by its extended neck, is a widely used flange type. Its design includes a tapered hub that gradually merges with the pipe. This tapering makes it ideal for high-pressure applications, as it distributes stress more evenly, reducing the risk of structural failure.

Advantages of Weld Neck Flanges:

- Excellent structural integrity and strength.

- Ideal for high-pressure and high-temperature applications.

- Reduces the risk of leakage due to its long neck.

- Resists deformation under extreme conditions.

Limitations of Weld Neck Flanges:

- It’s more expensive compared to some other flange types.

- Installation can be more time-consuming due to welding requirements.

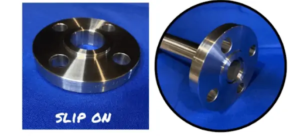

2. Slip-On Flange

Slip-on flanges are recognizable by their slightly larger diameter compared to the pipe they connect. They slide over the pipe and are then welded in place. This type of flange is commonly used in less critical applications where the expense of a weld-neck flange is not justified.

Advantages of Slip-On Flanges:

- Easier and quicker to install compared to weld neck flanges.

- Cost-effective for low-pressure and non-critical applications.

- A smooth internal bore minimizes turbulence in the pipeline.

Limitations of Slip-On Flanges:

- Lower strength and structural integrity compared to weld neck flanges.

- Not suitable for high-pressure or high-temperature systems.

3. Blind Flange

Blind flanges are solid disks used to block off the end of a pipe or to create a stop. They are typically used in systems that require periodic inspection or cleaning, as they provide easy access to the pipe. Blind flanges also find use in closing the ends of piping systems that are no longer in operation.

Advantages of Blind Flanges:

- Provides a secure closure for pipes and vessels.

- Facilitates inspection and cleaning of the pipeline.

- Ideal for isolating sections of a piping system.

Limitations of Blind Flanges:

- It is not designed for connecting pipes or components.

- Limited structural strength compared to other flange types.

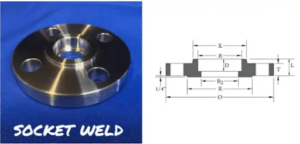

4. Socket Weld Flange

Socket weld flanges have a socket or female end into which the pipe is inserted. A fillet weld is used to join the pipe and flange. These flanges are well-suited for small-diameter, high-pressure applications, such as those found in the petrochemical industry.

Advantages of Socket Weld Flanges:

- Ideal for high-pressure and small-bore applications.

- A smooth bore minimizes turbulence and pressure drop.

- Provides for easy alignment of pipes during welding.

Limitations of Socket Weld Flanges:

- Limited to smaller pipe sizes.

- Requires precision during installation to ensure a proper fit.

5. Threaded Flange

Threaded flanges are equipped with threads on the inner bore, allowing them to be screwed onto threaded pipes or fittings. They are commonly used in low-pressure and low-temperature applications where welding is not preferred.

Advantages of Threaded Flanges:

- No welding is required, making them easy to install and remove.

- Suitable for smaller pipe sizes.

- It can be used in applications where disassembly is frequent.

Limitations of Threaded Flanges:

- Limited to low-pressure and low-temperature systems.

- Vulnerable to leakage if not properly sealed.

6. Lap Joint Flange

Lap joint flanges, consist of two parts: a stub-end and a loose backing flange. They are used in systems requiring frequent dismantling and cleaning. The stub end is welded to the pipe, while the backing flange can be rotated for alignment during assembly.

Advantages of Lap Joint Flanges

- Easy alignment and assembly due to the loose backing flange.

- Suitable for systems requiring frequent disassembly.

- Resists corrosion in various environments.

Limitations of Lap Joint Flanges

- Lower pressure handling capability compared to some other flange types.

- The assembly can be more complex than other flange types.

Functions of Pipe Flanges

The utility of pipe flanges extends far beyond mere connections. In this section, we will explore the multifaceted functions of pipe flanges, including:

1. Connecting Pipes and Components

Pipe flanges serve as the essential bridge connecting pipes and various components within an industrial system. Their circular design with bolt holes provides a secure and reliable method for joining pipes, valves, pumps, and other equipment.

This function is fundamental to the operation of any piping system, ensuring that fluids or gases can flow seamlessly from one component to another without leakage or compromise in structural integrity. In contrast, slip-on flanges, while easier to install, are better suited for low-pressure and non-critical applications where structural integrity is not a primary concern.

2. Providing Leak-Free Seals

In the realm of piping systems, leaks are the arch-nemesis. Pipe flanges, in collaboration with gaskets, are the frontline defense against leaks. Gaskets are inserted between the flange faces to create a tight seal. When the flange bolts are tightened, they compress the gasket, forming a leak-free connection. The type of gasket used depends on the fluid or gas being transported and the operating conditions.

3. Supporting High-Pressure Systems

One of the most demanding challenges in the world of piping systems is handling high-pressure applications. In high-pressure environments, the choice of flange type becomes crucial. Weld neck flanges, thanks to their tapered hub design, are often preferred in such scenarios. This design not only enhances structural integrity but also helps in the uniform distribution of stress.

4. Allowing for Easy Maintenance

Maintenance and repairs are inevitable in any industrial system. Flanges allow for easy access to specific sections of the piping system without the need to dismantle the entire structure. This not only saves time but also reduces the cost and complexity of maintenance operations. In addition, flanges can be quickly unfastened and resealed, minimizing downtime and ensuring that the system can return to full operation with minimal disruption.

Flange Installation:

Step-by-Step Guide to Installing Pipe Flanges:

1. Bolting Procedure

Installing pipe flanges involves a precise bolting procedure:

- Inspection: Before installation, inspect the flanges, gaskets, and bolts for any damage or defects. Ensure they are clean and free of debris.

- Lubrication: Apply an appropriate lubricant to the bolt threads and nut surfaces. This reduces friction during tightening and promotes even bolt load distribution.

- Bolt Insertion: Insert the bolts through the flange bolt holes and align them with the corresponding holes on the mating flange.

- Gasket Placement: Place the gasket between the flange faces, ensuring it is centered and properly aligned with the bolt holes.

- Hand-Tightening: Hand-tighten the nuts on the bolts in a crisscross pattern to evenly compress the gasket.

- Torqueing: Use a torque wrench to tighten the bolts in a specific sequence and to the recommended torque value. Refer to manufacturer specifications for the correct torque values.

- Inspection and Retightening: After initial torquing, inspect the flange connection for any irregularities or leaks. Depending on the system, it may be necessary to retighten the bolts after a specified period.

2. Gasket Installation

Proper gasket installation is essential for creating a reliable seal:

- Gasket Selection: Choose the gasket material based on compatibility with the fluid, temperature, and pressure of the system. Common gasket materials include rubber, graphite, and PTFE.

- Clean Flange Faces: Ensure that the flange faces are clean, free of debris, and in good condition. Any imperfections can lead to leaks.

- Gasket Placement: Center the gasket between the flange faces, aligning it with the bolt holes. Ensure that the gasket is not twisted or wrinkled.

- Proper Compression: Achieve the recommended compression by following the specified bolt tightening sequence and torque values.

- Avoid Overcompression: Be cautious not to over-tighten the bolts, as this can damage the gasket and compromise the seal.

Conclusion

In this comprehensive guide, we’ve embarked on a journey through the world of pipe flanges. From understanding the different types and their unique characteristics to grasping the crucial functions of flanges in industrial systems, we’ve provided you with a solid foundation of knowledge.

You’ve learned how to install pipe flanges correctly, maintain their integrity, and make informed decisions when selecting the right flange for your specific applications. By mastering these aspects of pipe flanges, you are better equipped to ensure the safety, efficiency, and reliability of your industrial systems.

For further information and expert insights on pipe flanges and related topics, feel free to explore our website: https://www.texasflange.com/lp12/